Projects blast rooms and blast robots abrasive cleaner model k750 supply vacuum blast machines to ship building industry airblastechtips airblastechtips tip 17 daily checklist blasting and safety com tip 16 abrasive profile comparative chart.

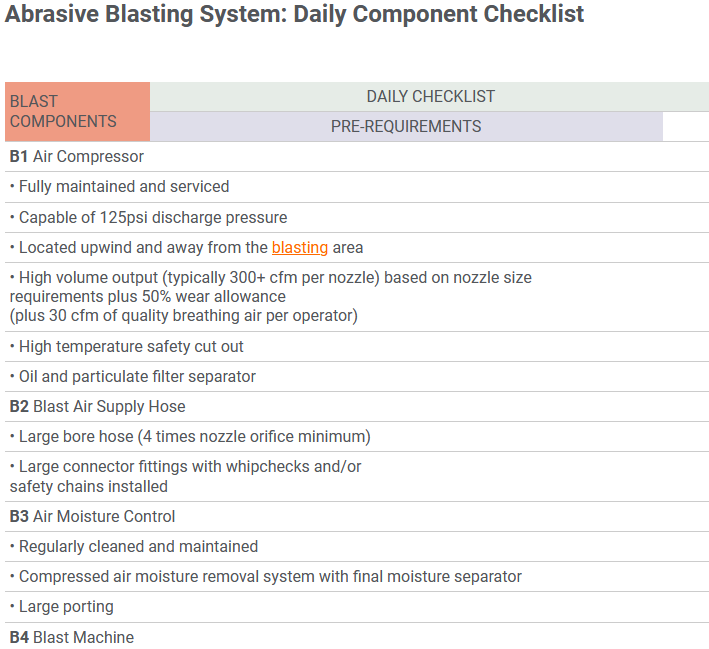

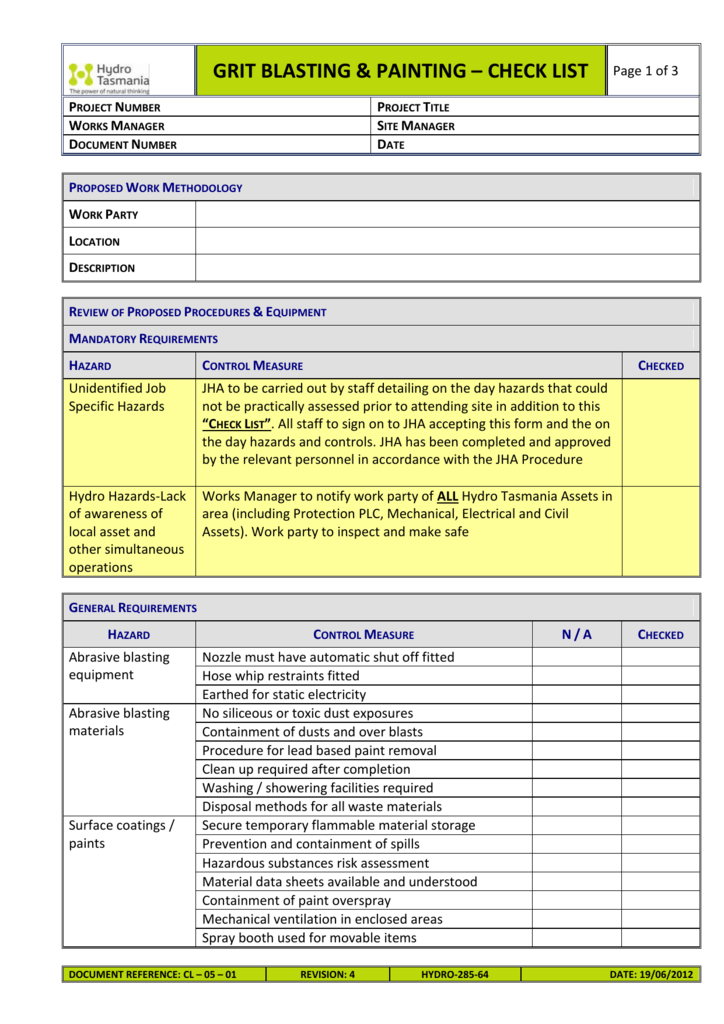

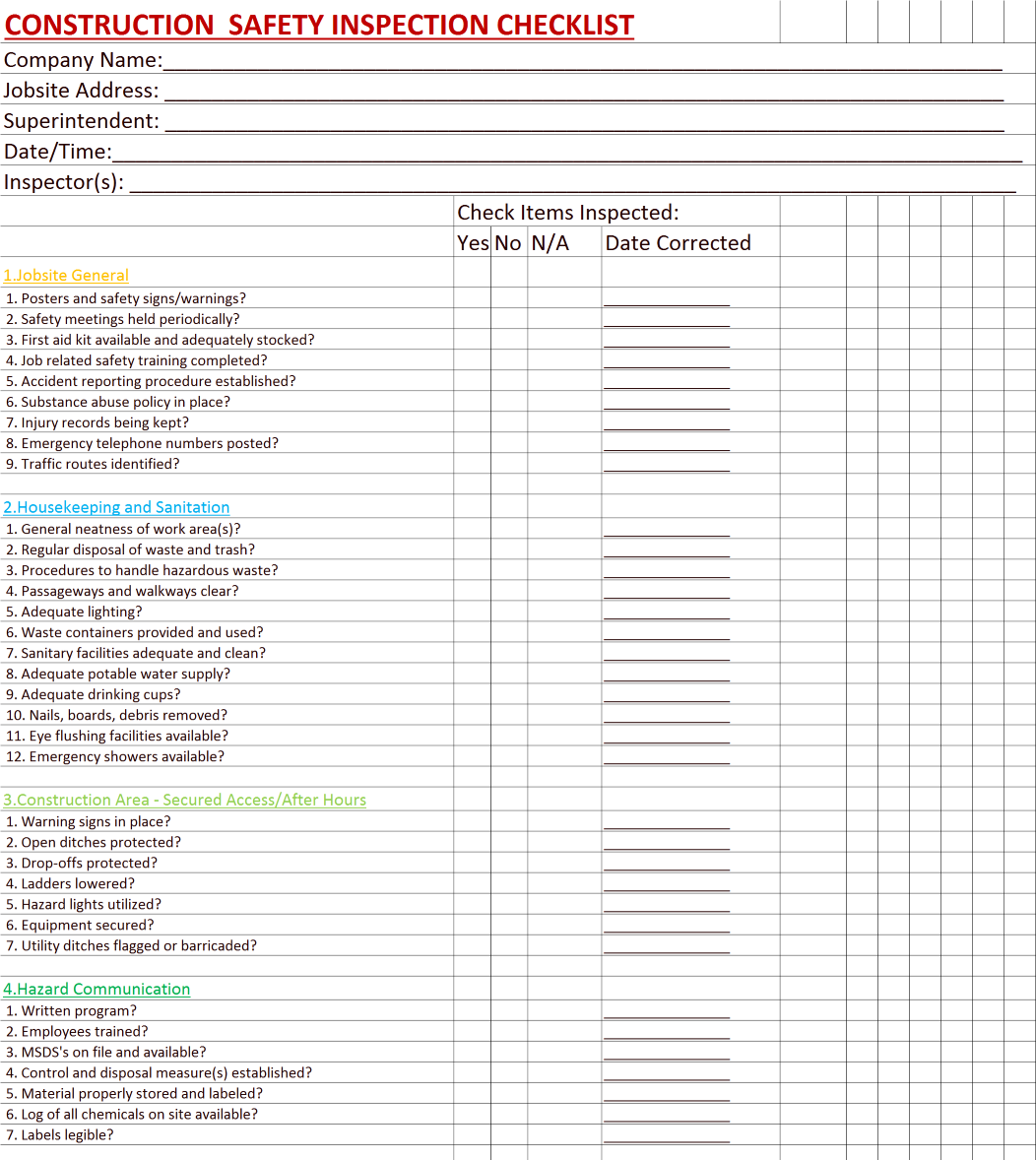

Abrasive blasting equipment checklist.

One of the most basic forms of blasting defence and safety is a blasting checklist.

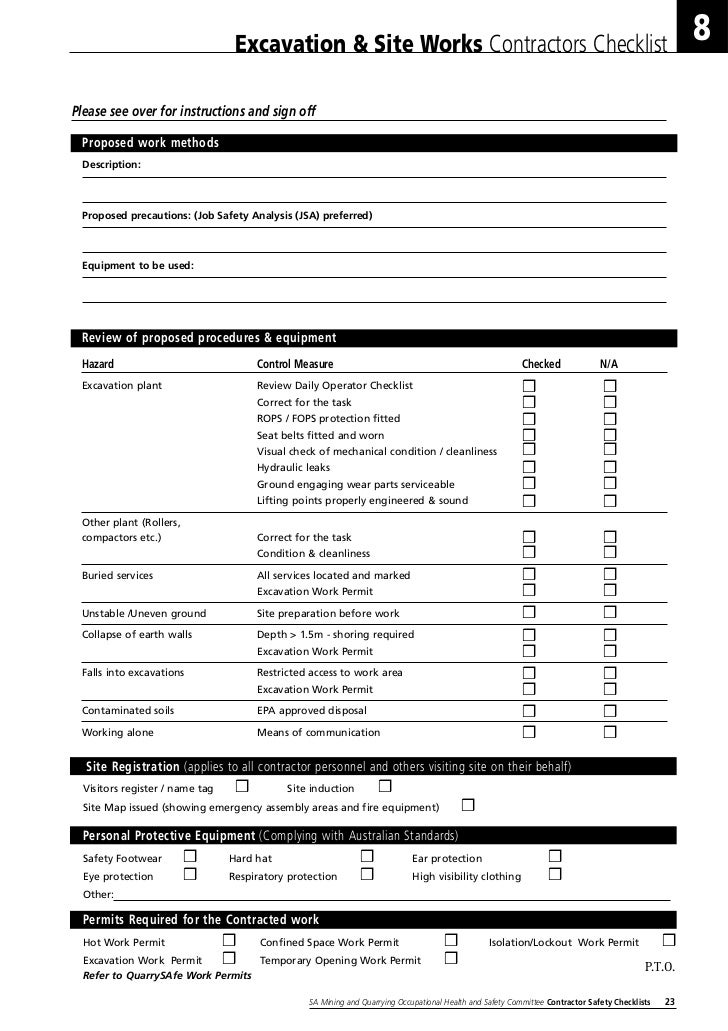

Is the scaffolding equipment equipped with the appropriate guard rails and work platforms.

Abrasive blasting checklist veracity field services date.

Graco abrasive blasters are ideal for blasting in areas where dust and containment are concerns.

Abrasive blasting uses a lot of force to complete a job well and.

High pressure objects can strike workers and other people and the equipment being used to perform blasting is inherently destructive and therefore dangerous.

This method is ideal for surface preparation and provides a cleaner surface with little to no embedded particles or clinging dust.

Manual blast cabinets enclosed blasting in a cabinet protects blast operators and nearby workers from inhalation hazards and also shields them and the work area from abrasive rebound.

Pressure washers equipment.

Air compressors dryers.

Abrasive blasting can generate toxic dust.

Abrasive blasting is used in a variety of industries from shipbuilding to the automotive industry.

Download your free painting and blasting risk assessment checkliststo make your life easier we ve created a daily component and work risk assessment checklist to make sure you have all of the equipment you need to complete your jobs successfully.

Is the staging surfaces level smooth and free of obstructions.

Blast hoods and accessories.

Abrasive media posts to help select the correct type grade and calculations when blasting.

Supplied air respirators sars carbon monoxide monitors alarms and all of the other personal protective equipment ppe needed for safe and compliant blasting.

Thanks to abrasive blasting businesses can efficiently prepare and clean various surfaces for paint or sealant applications.

Blast rooms and spray booths.

Inspection completed by.

Wet and vapor abrasive blast systems employ a mixture of water air and abrasive to clean and remove surface contaminants and coatings.